LAND FILLING AT GOVT. APPROVED LAND FILL SITES

INCINERATION BY GOVT. APPROVED INCINERATORS

COPROCESSING IN CEMENT KILNS

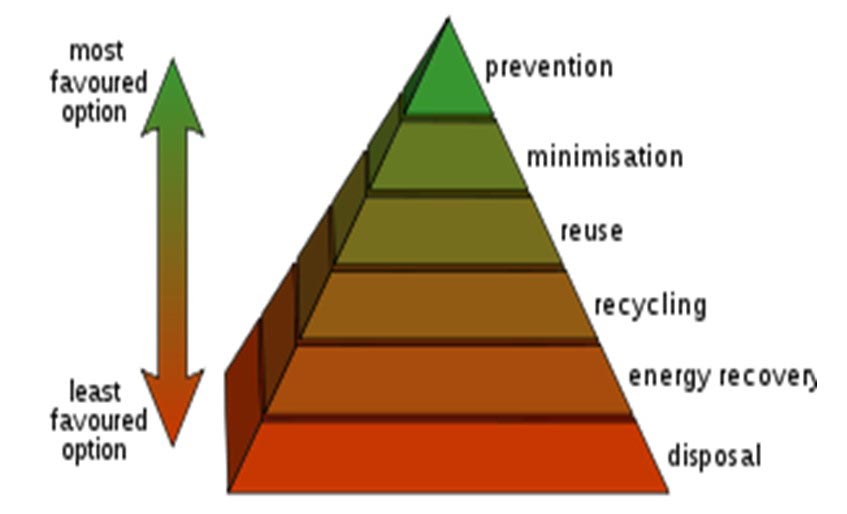

The other way to dispose off the paint sludge i.e.. (Hazardous Waste) is the disposition of hazardous waste at government approved Hazardous disposal sites after due testings and treatments. Land availability is always limited and beyond

limit these sites would no longer be available. Also dumping hazardous waste under soil means poisoning our future with increasing the toxins of soil and water.

Incineration is depletion of Natural resources as ONE TON OF PAINT SLUDGE REQUIRES 110 KGS OF FUEL (HSD) .This itself is not a neat remedy as it leaves behind 20-36% ash containing hazardous metallic oxides and also emits a lot of Carbonic gases leading to pollution .This ash produced again needs to be handled as Hazardous Waste.

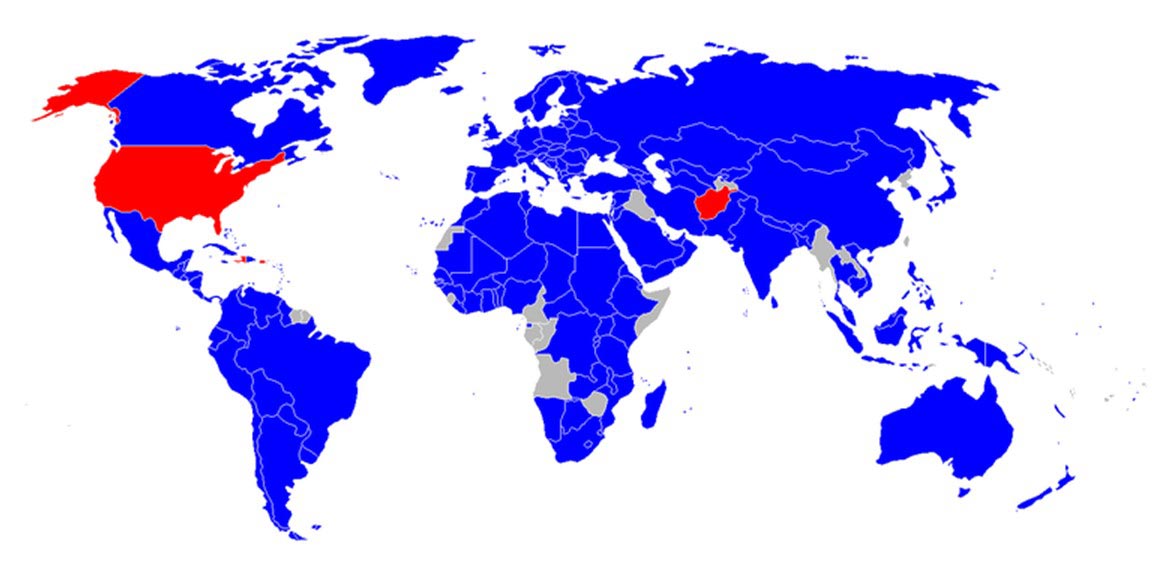

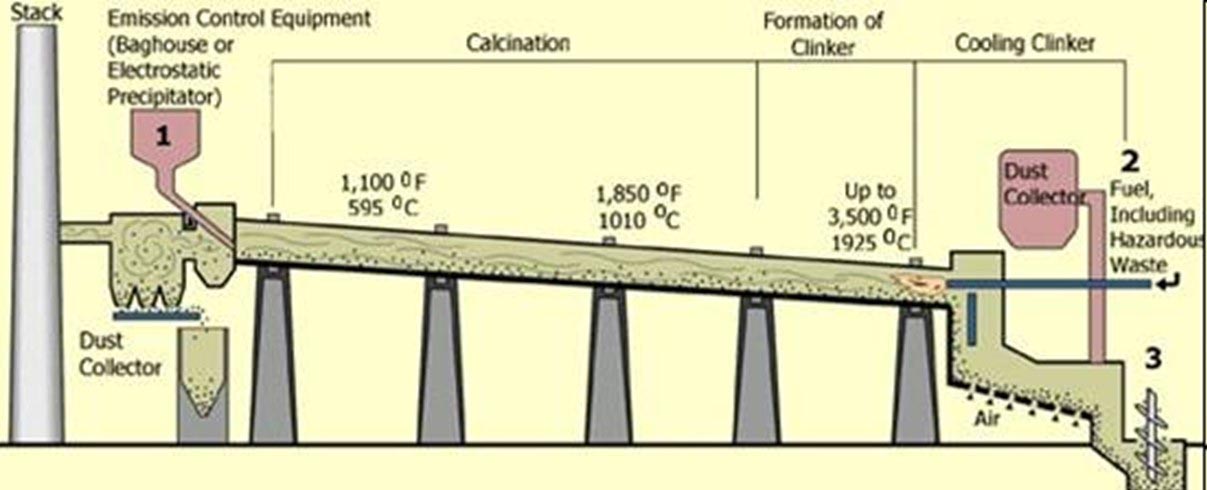

Co-processing of Hazardous waste in Cement Kilns means using hazardous waste as an alternate fuel . Throughout the world some 60 cement kilns have been modified so that various wastes can be burned along with conventional fuels. But cement kilns are designed to make cement and not to dispose of waste.

According to a study by the US Center for the Biology of Natural Systems, emissions of dioxins are eight times higher from cement kilns burning hazardous waste, than from those that do not burn it

Co Processing is also a potential hazard for the environment. In timing for the heat in the Kiln, as well as the temperature, is not necessarily the same as the requirements for the best possible hazardous waste incineration. Therefore the operation for making cement leaves the process for hazardous waste incineration incomplete, and therefore more polluting. All bottom and fly ash and liquid scrubber waste from hazardous waste incinerators is a Hazardous waste under U.S. Hazardous waste laws (RCRA) , but cement kilns and light-weight aggregate kilns (LWAK) sell a “product” and so their ash is not regulated as a hazardous waste!

Far from making waste disappear incinerators actually create more toxic waste, and through this pose a significant threat to public health and the environment. Incinerator ashes – contaminated with heavy metals, unburned chemicals and entirely new chemicals formed during the burning process – are buried in landfill or dumped in the environment. One of the most insidious aspects of incineration is the entirely new and highly toxic chemicals that can be formed during the combustion process.

Dioxins and furans (often referred to just as dioxins) – a class of chemical compounds widely recognised to contain many highly toxic compounds including TCDD, a chemical which has been described as the most toxic chemical known to man.

Dioxins are created when chlorine-containing materials are burned. They have no useful purpose and are associated with a wide range of health impacts including, cancer, altered sexual development, male and female reproductive problems, suppression of the immune system, diabetes, organ toxicity and a wide range of effects on hormones.

THE PAINT SLUDGE IS CLASSIFIED AS HAZARDOUS INDUSTRIAL WASTE UNDER THE HAZARDOUS WASTE RULES, 1989 AS AMENDED UP TO MAY 2003 (SECTION –21.1). AND UNDER THE ORDERS PROMULGATED BY HONOURABLE SUPREME COURT OF INDIA, IN SLP (C) NO. 16175 / 1997 AND C.A. NO. 7660 / 1997, ITS REMOVAL OUT OF THE PREMISES OF INDUSTRIAL UNIT PRODUCING IT IS PROHIBITED, THIS CAN ONLY BE TRANSPORTED TO A GOVT. APPROVED DISPOSAL SITE – THROUGH A GOVT. LICENCED TRANSPORTER – WITH DUE PERMISSION FROM STATE P.C.B.

Ship – Khian Sea, carrying incinerator ash from Philadelphia dumped 50% of its load into the sea of Haiti and was forced away wherein it sailed for many months changing its name several times. Unable to unload, the crew dumped much of the load into sea.

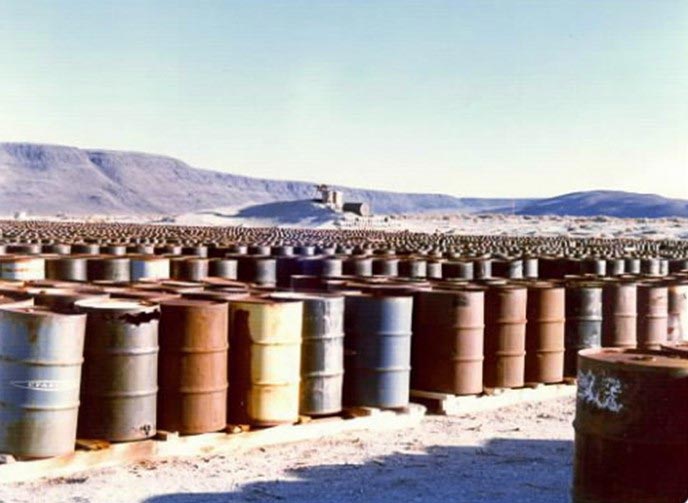

1988 8000 barrels of hazardous waste from Italy shipped into Nigeria in exchange of $100 per month as rent given to the farmer.